Pyrolysis

Pyrolysis is a thermal conversion process that breaks down organic materials at high temperatures in the absence of oxygen, producing fuels, biochar, and other valuable byproducts.

Pyrolysis

Pyrolysis is a thermal conversion process that breaks down organic materials at high temperatures in the absence of oxygen, producing fuels, biochar, and other valuable byproducts.

Pyrolysis Insights

- Scores

- Sustainability Insights

- Photos

- Video

- How It Works

- Sustainability Impact

- Cost and Affordability

- DIY and Community Use Cases

- Scalability & Industry Applications

- Innovation Metrics & Performance Data

- Alignment with Global Sustainability Goals

- Renewable Energy & Resource Integration

- Education & Awareness Potential

- The Future of This Innovation

✅ Overall Impact Score

♻️ Circularity Score

⚡ Energy Efficiency Score

🌱 Environmental Impact Score

💰 Affordability Score

🔋 Renewable Integration Score

🛠️ DIY Accessibility Score

📈 Scalability Score

🧪 Innovation Score

💡 Practical Usability Score

🌍 Global Sustainability Alignment Score

📦 Material Sustainability Score

🏘️ Community Impact Score

🚚 Supply Chain Sustainability Score

🧠 Educational Value Score

🚀 Future Readiness Score

🔒 Disclaimer

The information provided on this page is for educational and informational purposes only. While Sustainable World strives to ensure the accuracy and relevance of the content, including innovation scores, environmental impact claims, and sustainability assessments, we do not guarantee completeness, accuracy, or timeliness.

🔬 All innovation insights, metrics, and scoring systems reflect Sustainable World‘s independent analysis and methodology. These are not endorsements or certifications of product safety, environmental claims, or regulatory compliance. Users should conduct their own research or consult qualified professionals before acting on any information found here.

💡 Some insights may be influenced by AI-assisted content generation and publicly available data, which we analyze and format using proprietary frameworks. Always verify technical, scientific, or safety data with original sources when making decisions related to environmental practices, purchasing, or implementation.

🔗 This site contains affiliate links to third-party products or services. We may earn a commission at no additional cost to you if you make a purchase through these links. However, product inclusion does not imply sponsorship or official partnership unless explicitly stated.

💼 Innovations, technologies, and sustainability practices vary widely by location, application, and scale. Suitability, performance, and feasibility will differ based on local infrastructure, regulations, and individual context.

📉 Sustainable World is not liable for any direct or indirect damages or losses incurred from the use of information on this site.

Overview:

Pyrolysis is an innovative solution that transforms waste—such as plastics, biomass, and tires—into usable outputs like synthetic gas, bio-oil, and solid carbon (biochar). By heating materials in an oxygen-free environment, pyrolysis decomposes complex molecules into simpler compounds without combustion. This method is increasingly being used for sustainable waste management, renewable energy production, and soil regeneration through biochar application. Its ability to reduce landfill reliance, capture carbon, and produce clean energy makes it a promising tool in addressing both environmental degradation and energy needs.

🌱 Environmental Impact

📉 Waste Reduction

Capable of diverting up to 90% of certain waste streams (e.g., plastics, tires, biomass) from landfills, pyrolysis provides a second life to materials that would otherwise pollute.

💧 Resource Conservation

By recovering valuable energy and materials from waste, pyrolysis reduces reliance on virgin fossil fuels and minimizes the extraction of raw resources.

⚡ Energy Efficiency

While pyrolysis requires energy input, modern systems use part of the synthetic gas produced to power themselves, making them increasingly energy-efficient and self-sustaining.

🔁 Circular Economy Integration

Pyrolysis turns waste into usable energy, char, or chemicals, closing the loop on difficult-to-recycle materials and supporting a regenerative resource cycle.

📦 Material Innovation

The biochar and oils derived can be used in agriculture, construction, and even as industrial feedstock, replacing less sustainable inputs.

🧪 Scientific Breakthrough

Advances in reactor design, feedstock preprocessing, and temperature control have made pyrolysis commercially viable and environmentally sound.

💡 Cost-Effectiveness

Though initial capital investment is high, pyrolysis offers strong ROI through energy sales, reduced waste disposal costs, and byproduct monetization (e.g., biochar).

📊 Impact Metrics

Key metrics include waste diverted per ton, CO₂e avoided, kWh generated, and biochar yield per input volume—many systems show positive net energy gain.

📱 Tech Integration

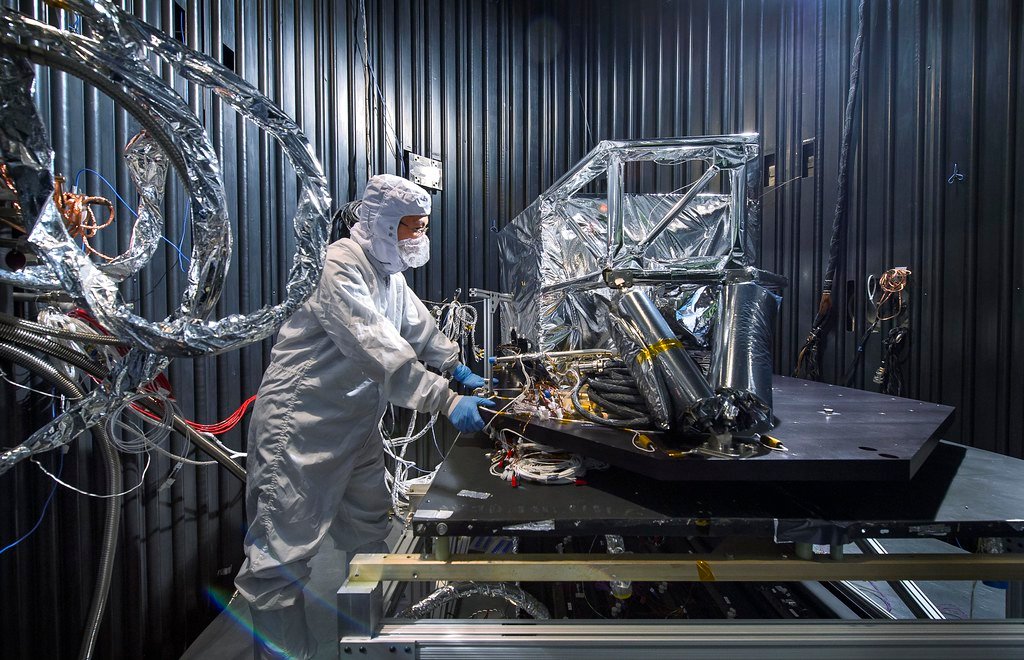

Some systems integrate IoT sensors and AI for real-time monitoring and optimization of temperatures, pressure, and output yield.

🧭 Alignment with SDGs

Supports UN SDGs including:

-

SDG 7: Affordable and Clean Energy

-

SDG 11: Sustainable Cities and Communities

-

SDG 12: Responsible Consumption and Production

-

SDG 13: Climate Action

🏘️ Community Benefit

Offers decentralized waste and energy solutions, reduces health hazards from open burning, and creates green jobs in local recycling or energy sectors.

📚 Educational Value

Used in sustainability education programs to demonstrate thermochemical conversion and circular economy in action.

🏗️ Built Environment Compatibility

While not a building material, pyrolysis plants can be integrated into eco-industrial parks or local waste recovery infrastructure.

🚀 Future Potential

As regulations on plastic waste tighten and carbon credits expand, pyrolysis could become a key player in urban waste systems and decentralized energy production.

🎯 Target Market Fit

Ideal for municipalities, agricultural cooperatives, recycling firms, and energy producers seeking innovative waste-to-energy systems.

📉 Lifecycle Assessment

Lifecycle studies show significant net positive environmental impact when emissions, material recovery, and energy offset are considered.

🏭 Industrial Applications

Deployed in industries like plastic recycling, agriculture, oil recovery, and even in green hydrogen production via bio-oil reforming.

🛠️ DIY Applications

Due to the high heat and emissions risks, pyrolysis is generally not recommended for DIY setups. However, small-scale biochar kilns are a safe and accessible version of this technology for gardeners and farmers.

🌍 Global Scalability

Already in use in Europe, Asia, and parts of the U.S.—pyrolysis is scalable in both developed and emerging markets, especially where waste infrastructure is lacking.

🛠️ Ease of Implementation

Requires technical expertise and permitting, but modular pyrolysis systems are being developed to simplify adoption in smaller communities and businesses.

🔒 Disclaimer

The information provided on this page is for educational and informational purposes only. While Sustainable World strives to ensure the accuracy and relevance of the content, including innovation scores, environmental impact claims, and sustainability assessments, we do not guarantee completeness, accuracy, or timeliness.

🔬 All innovation insights, metrics, and scoring systems reflect Sustainable World‘s independent analysis and methodology. These are not endorsements or certifications of product safety, environmental claims, or regulatory compliance. Users should conduct their own research or consult qualified professionals before acting on any information found here.

💡 Some insights may be influenced by AI-assisted content generation and publicly available data, which we analyze and format using proprietary frameworks. Always verify technical, scientific, or safety data with original sources when making decisions related to environmental practices, purchasing, or implementation.

🔗 This site contains affiliate links to third-party products or services. We may earn a commission at no additional cost to you if you make a purchase through these links. However, product inclusion does not imply sponsorship or official partnership unless explicitly stated.

💼 Innovations, technologies, and sustainability practices vary widely by location, application, and scale. Suitability, performance, and feasibility will differ based on local infrastructure, regulations, and individual context.

📉 Sustainable World is not liable for any direct or indirect damages or losses incurred from the use of information on this site.

🌱 How It Works: Pyrolysis Technology

Pyrolysis is a thermal decomposition process that breaks down organic materials—such as plastic, rubber, or biomass—into usable products like synthetic gas, bio-oil, and solid carbon (often in the form of biochar). This transformation occurs in the absence of oxygen, which prevents combustion and allows the feedstock to decompose at high temperatures (typically between 300°C and 600°C).

Here’s a simplified breakdown of the pyrolysis process:

🔽 Input Stage

Feedstock materials such as plastic waste, used tires, agricultural residue, or wood chips are fed into a sealed reactor. These materials are usually shredded or prepared to ensure uniform thermal exposure.

🔥 Thermal Decomposition

Inside the reactor, the feedstock is heated indirectly (without oxygen) using external sources. As the temperature rises, long-chain hydrocarbons in the material begin to break down into smaller molecules through a chemical process known as cracking.

💨 Vaporization and Gas Separation

The heat produces vapors that are cooled and condensed into bio-oil or liquid fuel, while non-condensable gases (like syngas) can be captured and used as an energy source for the system itself, increasing its energy efficiency.

⚫ Solid Output

The solid byproduct, biochar or carbon black (depending on the material), is collected. Biochar is often used in soil amendment, while recovered carbon from tires or plastics can be used in manufacturing or energy.

♻️ Energy Recirculation (if applicable)

Some pyrolysis systems are designed to use the energy produced from syngas to power the heating system, creating a self-sustaining loop that enhances overall efficiency and reduces external energy needs.

✅ What Makes Pyrolysis Unique?

-

No combustion means fewer emissions and pollutants.

-

Capable of transforming hard-to-recycle waste into valuable outputs.

-

Can be modular and scalable—used in both urban and rural setups.

-

Outputs like biochar and oil have economic and environmental benefits.

Pyrolysis represents a compelling approach to converting waste into value while reducing dependence on landfills and fossil fuels. It’s not just a waste treatment solution—it’s a key link in building circular and regenerative systems for a sustainable future.

🌱 Sustainability Impact of Pyrolysis

Pyrolysis technology has emerged as a powerful tool in the shift toward circular and sustainable systems. By converting waste into usable resources, it not only reduces environmental degradation but also supports energy recovery, material reuse, and carbon sequestration. Below are the key areas where pyrolysis delivers measurable sustainability impact:

🌍 Environmental Impact

Pyrolysis significantly reduces air and soil pollution by diverting non-biodegradable waste—such as plastics and tires—from landfills and incineration. Unlike incineration, it operates in an oxygen-free environment, which minimizes harmful emissions such as dioxins and furans. Its byproducts (biochar, gas, and oil) can replace fossil fuels and carbon-intensive materials.

📉 Waste Reduction

This technology can divert up to 90% of incoming waste from landfills, turning it into usable outputs. For example, 1 ton of plastic waste can yield around 700 liters of oil, gas for on-site energy, and solid carbon, reducing waste stockpiles and pressure on municipal systems.

💧 Resource Conservation

Pyrolysis supports resource efficiency by recovering materials and energy from waste without the need for water-intensive processes. Additionally, biochar produced through biomass pyrolysis can be used to enhance soil fertility, reduce fertilizer dependence, and improve water retention in agriculture.

⚡ Energy Efficiency

Some pyrolysis systems are designed to be energy self-sufficient by using the syngas (a byproduct) to fuel their own heating mechanisms. This closed-loop energy use minimizes external fuel needs and enhances the energy return on input.

🔁 Circular Economy Integration

Pyrolysis aligns with circular economy principles by transforming waste into raw materials for new products. The outputs—bio-oil, biochar, and carbon black—can be reused in agriculture, construction, and fuel production, effectively closing the loop on waste streams.

In short, pyrolysis serves as a bridge between waste reduction, renewable energy generation, and sustainable manufacturing. It turns pollution into possibility—delivering a suite of environmental, economic, and social benefits that support global sustainability efforts.

💰 Cost, ROI, and Affordability of Pyrolysis Technology

Pyrolysis systems can vary widely in cost depending on scale, feedstock type, and intended use (industrial, municipal, or pilot-scale). While the initial capital investment for a pyrolysis plant is relatively high compared to traditional waste management methods, the long-term return on investment (ROI) can be substantial due to multiple revenue streams and cost savings.

💸 Upfront Costs

-

Small-scale units (for research or local pilot projects): $10,000–$50,000

-

Medium to large-scale plants (municipal or industrial use): $500,000–$5 million+

-

Costs typically include engineering, feedstock processing systems, reactors, filtration, and energy integration components.

📈 Return on Investment

-

Multiple revenue streams: Pyrolysis oil can be refined or sold, biochar has agricultural value, and syngas can power operations.

-

Reduced landfill fees: Municipalities can save significantly on tipping and transport costs.

-

Energy savings: Facilities can use their own syngas to run the system, cutting operational energy costs.

Depending on the business model, ROI can range from 2 to 7 years, with higher efficiency and local feedstock access reducing this window.

🤝 Affordability for Communities & Businesses

-

Modular designs are emerging that make the technology more accessible to small communities and businesses.

-

In developing regions, pyrolysis units are increasingly viewed as both waste solutions and micro-enterprise opportunities for turning agricultural or plastic waste into sellable outputs.

🔄 Cost-Benefit Summary

While pyrolysis isn’t yet the most affordable option for all applications, its potential to generate value from waste, reduce environmental fees, and provide long-term economic returns makes it a smart investment—especially when supported by government grants, carbon credits, or sustainability incentives.

In short: High upfront cost, but high long-term value.

🛠️ DIY and Community Use Cases for Pyrolysis Technology

While industrial-scale pyrolysis systems are complex and costly, there is growing interest in small-scale, community-based, and educational applications of pyrolysis—especially for converting biomass or plastic waste into usable energy or materials.

🔧 DIY Applications: Proceed with Caution

-

Basic pyrolysis units can be built for educational or experimental purposes using steel drums or kilns to convert biomass (like wood chips or agricultural waste) into biochar.

-

These systems require careful ventilation, temperature control, and safety precautions. They are not recommended for plastic pyrolysis due to toxic gas emissions and fire risk.

-

DIY biochar production is more common and safer, often used in permaculture, gardening, and regenerative agriculture.

⚠️ Important Note: Plastic pyrolysis should never be attempted as a DIY project without industrial-grade filtration, containment, and safety systems due to the risk of dioxin release, explosion, and environmental harm.

🌱 Community-Level Pyrolysis Projects

-

Biochar kilns are being deployed in community gardens and regenerative farms to improve soil health, sequester carbon, and reduce organic waste.

-

Educational institutions use pyrolysis for teaching sustainable waste-to-energy solutions and environmental science.

-

Some municipalities and local cooperatives are exploring containerized pyrolysis units that can be deployed for managing agricultural residue or forestry waste.

🤝 Use Case Highlights

-

Farmers turning crop waste into soil-enhancing biochar.

-

Rural communities using small pyrolysis units to manage biomass and reduce smoke from open burning.

-

Nonprofits using the technology for sustainable development projects tied to clean energy and carbon sequestration.

✅ Best DIY/Community Uses

-

Biochar production for gardening/agriculture

-

Educational demonstrations and pilot projects

-

Organic waste reduction in low-resource settings

In summary, while pyrolysis for plastics and fuel generation is best left to professionals, biochar-focused pyrolysis offers safe, scalable, and impactful use cases for DIY enthusiasts and communities aiming to reduce waste and improve soil health sustainably.

📈 Scalability & Industry Applications of Pyrolysis

Pyrolysis technology has proven to be a highly scalable solution for both waste management and resource recovery across a variety of industries. As global pressure mounts to reduce landfill reliance, cut emissions, and find alternatives to fossil fuels, pyrolysis offers a flexible and adaptive model for sustainable transformation.

🔩 Industrial Scalability

-

Modular design allows pyrolysis plants to scale from small community units to large industrial facilities processing thousands of tons of waste annually.

-

Scalable systems can be tailored to specific feedstocks (e.g., plastics, rubber, wood, sewage sludge, or agricultural waste), optimizing outputs such as fuel, carbon black, or biochar.

-

Industrial pyrolysis units can be containerized for deployment in remote areas or urban hubs needing decentralized waste-to-energy systems.

🏭 Key Industry Applications

1. Plastic Waste Management

-

Chemical recycling of plastics into synthetic fuel or feedstock.

-

Reduces landfill overflow and complements mechanical recycling programs.

2. Agriculture & Forestry

-

Biomass pyrolysis generates biochar, a soil enhancer that also locks in carbon.

-

Used in carbon credit markets and regenerative agriculture.

3. Oil & Gas

-

Produces alternative liquid fuels such as pyrolysis oil, which can be refined into diesel.

-

Offers fuel substitution strategies for remote or off-grid areas.

4. Automotive & Tire Industry

-

Converts waste tires into recovered carbon black, steel, and pyrolysis oil.

-

Reduces hazardous tire stockpiles and enables circular resource flow.

5. Municipal Waste Processing

-

Municipal Solid Waste (MSW) pyrolysis units are emerging as alternatives to incineration.

-

Lower emissions and potential for cleaner energy recovery.

6. Construction & Demolition Waste

-

Organic building materials and treated woods can be broken down through pyrolysis, minimizing landfill usage.

🌍 Scalability Across Regions

-

Pyrolysis is gaining traction globally in countries such as India, China, the U.S., and EU nations, thanks to supportive policies for circular economy and low-emission innovation.

-

Ideal for developing nations where centralized waste systems are lacking—creating off-grid, revenue-generating microplants.

🚀 Growth Outlook

-

As environmental regulations tighten and fossil fuel alternatives gain demand, pyrolysis is projected to grow significantly across chemical, energy, waste management, and agriculture sectors.

-

Industry forecasts predict the global pyrolysis market to exceed $8 billion by 2030, with increasing adoption in urban and industrial ecosystems.

In conclusion, pyrolysis is no longer an experimental solution—it is a rapidly deployable, regionally adaptable innovation with deep roots across industry verticals. Its potential to close material loops, reduce carbon, and fuel the green economy positions it as a cornerstone of future sustainability infrastructure.

📊 Innovation Metrics & Performance Data for Pyrolysis

Pyrolysis technology stands out due to its quantifiable environmental and energy recovery benefits. Its ability to convert waste into valuable resources has been studied extensively, with consistent metrics demonstrating strong performance in waste reduction, emissions control, and circular resource generation.

🔥 Energy Recovery Efficiency

-

Energy Conversion Efficiency ranges from 60% to 75%, depending on feedstock type and reactor design.

-

For plastic-to-fuel applications, up to 70–80% of input material can be recovered as usable pyrolysis oil, with the remainder forming syngas and char.

🏭 Emissions & Pollution Control

-

Emits significantly fewer pollutants than traditional incineration methods.

-

Modern systems feature closed-loop gas capture, minimizing VOCs and particulates released during operation.

-

Many pyrolysis units meet or exceed EU and EPA air quality compliance standards.

♻️ Waste Diversion Metrics

-

Pyrolysis can divert up to 90% of treated waste from landfills, particularly effective for non-recyclable plastics, tires, and biomass.

-

A single mid-scale pyrolysis plant can process 10,000+ tons of waste annually, drastically reducing landfill dependency.

💡 Yield & Output Composition

-

Typical output breakdown for plastic pyrolysis:

-

45–60% pyrolysis oil

-

15–25% syngas

-

10–20% char or carbon black

-

-

Biomass pyrolysis can yield biochar with up to 80% carbon content, highly valuable for soil health and carbon sequestration.

📉 Carbon Emissions Impact

-

Each ton of plastic processed through pyrolysis can prevent up to 2.5–3 tons of CO₂-equivalent emissions compared to landfilling or incineration.

-

Biochar use in soil contributes to long-term carbon removal, aligning with negative emissions goals.

📈 Return on Investment (ROI) Metrics

-

Average ROI period for industrial-scale pyrolysis plants: 2–4 years, depending on feedstock availability, energy prices, and local regulations.

-

Facilities that integrate energy generation from syngas can offset operational costs significantly.

📦 Feedstock Versatility

-

Can process a wide variety of inputs:

-

Plastic types #1–7

-

Tires

-

Agricultural waste

-

Sewage sludge

-

Forestry residues

-

🧪 Research Benchmarks & Pilot Results

-

Recent pilot programs show 10–15% higher efficiency with catalytic and microwave-assisted pyrolysis.

-

AI-assisted monitoring systems are being developed to optimize reactor temperature, feed rates, and product output in real time.

Pyrolysis excels not just in theory but in measurable performance. Its strong innovation metrics showcase a technology that is already delivering real-world results—diverting waste, producing clean energy, and enabling circular material recovery—with scalability that supports its continued evolution as a leading sustainability solution.

🧭 Alignment with Global Sustainability Goals

Pyrolysis technology strongly aligns with multiple United Nations Sustainable Development Goals (UN SDGs), making it a vital innovation in the global shift toward sustainability and climate resilience. Its ability to transform waste into usable energy and materials supports both environmental and socioeconomic objectives across industries and regions.

♻️ SDG 12: Responsible Consumption and Production

Pyrolysis promotes resource efficiency by converting non-recyclable waste like plastics, tires, and biomass into valuable products such as oil, gas, and biochar. This supports a circular economy model and reduces the burden on landfills and incinerators.

🌍 SDG 13: Climate Action

By diverting carbon-heavy waste from landfills and reducing methane and CO₂ emissions, pyrolysis contributes to significant greenhouse gas reductions. Biochar, a byproduct of biomass pyrolysis, acts as a stable form of carbon storage—supporting negative emissions efforts.

💧 SDG 6: Clean Water and Sanitation

Biochar produced through pyrolysis is used in water filtration and soil remediation, helping remove toxins and heavy metals from contaminated environments—especially in agricultural and post-industrial areas.

🔋 SDG 7: Affordable and Clean Energy

The conversion of waste into syngas and liquid fuels creates alternative energy sources that reduce dependency on fossil fuels, especially in off-grid or energy-insecure communities.

🏘️ SDG 11: Sustainable Cities and Communities

Local pyrolysis units offer municipalities a way to manage urban waste sustainably, reduce landfill overflow, and generate clean energy or materials that can be reinvested into the local economy.

🏭 SDG 9: Industry, Innovation, and Infrastructure

Pyrolysis is a prime example of sustainable industrial innovation. It supports cleaner manufacturing processes, scalable infrastructure, and the modernization of waste management systems.

🌱 SDG 15: Life on Land

By reducing waste leakage into the environment and restoring degraded soils with biochar, pyrolysis contributes to land conservation, soil fertility, and biodiversity protection.

📚 SDG 4: Quality Education

As an emerging technology, pyrolysis provides educational opportunities for research institutions and technical training centers, promoting sustainability literacy in waste-to-energy science and environmental engineering.

In summary, pyrolysis is not just a waste solution—it’s a strategic sustainability tool that addresses climate, energy, education, industry, and community goals. Its adoption and development are key to meeting global sustainability benchmarks and accelerating the transition to a regenerative economy.

🔋 Renewable Energy & Resource Integration

Pyrolysis offers significant potential when it comes to integrating with renewable energy systems and conserving natural resources. While the process itself is not classified as a renewable energy source, it complements and enhances sustainability goals through resource circularity, energy recovery, and grid flexibility.

♻️ Energy Recovery from Waste

One of pyrolysis’ core strengths is its ability to convert non-recyclable waste—such as plastics, tires, and biomass—into usable energy products like pyrolysis oil, syngas (synthetic gas), and char. These outputs can:

-

Power turbines or generators in local microgrids.

-

Be refined into biofuels for transportation or industrial heating.

-

Serve as backup or base-load energy in hybrid renewable systems (alongside solar, wind, or hydro).

This positions pyrolysis as a reliable source of waste-derived energy, especially where renewables face intermittency.

🌱 Complement to Renewable Energy Systems

Pyrolysis systems can operate in conjunction with solar panels or wind turbines, using excess electricity during peak generation to process waste, especially in off-grid or developing regions. For example:

-

Biochar created from biomass pyrolysis can be used to improve soil carbon content, thus contributing to regenerative agriculture—further closing the loop between energy, food, and ecosystem resilience.

-

Syngas can serve as an energy buffer to stabilize local energy needs during low sunlight or wind periods.

💧 Natural Resource Conservation

By reducing the need for virgin fossil fuels and raw materials, pyrolysis helps conserve finite natural resources. It also:

-

Prevents environmental degradation from mining or oil extraction.

-

Reduces water pollution through better waste diversion.

-

Extends the lifecycle of materials that would otherwise be discarded.

In essence, pyrolysis doesn’t just integrate with renewable systems—it amplifies their potential. Through energy recovery, material circularity, and off-grid utility, it plays a strategic role in building resilient, resource-efficient energy ecosystems.

📚 Education & Awareness Potential

Pyrolysis holds powerful educational value as a real-world example of how science, engineering, and sustainability converge. Its multifaceted process offers students, professionals, and the public a tangible way to understand complex environmental challenges—and the innovative technologies solving them.

🧠 A Gateway to Environmental STEM Education

Pyrolysis can be used to teach:

-

Thermal decomposition chemistry (endothermic reactions, hydrocarbon chains, etc.)

-

Energy systems and fuel alternatives

-

Waste management science (plastics, biomass, tire recycling)

-

Lifecycle thinking and circular economy principles

It’s an ideal hands-on topic for high school and university STEM curricula, particularly in sustainability studies, chemical engineering, and environmental science.

🎓 Demonstration and Outreach Programs

Smaller-scale pyrolysis units can be used in:

-

Science museums and community centers to raise awareness about alternative waste-to-energy methods.

-

Vocational programs for green technology training.

-

Workshops and maker labs to demonstrate grassroots or village-scale energy solutions.

These educational settings provide a unique way to show how waste can be transformed into value—encouraging innovation at both grassroots and academic levels.

🌍 Driving Public Awareness and Behavior Change

Public exposure to pyrolysis systems through documentaries, media, and municipal pilot projects helps:

-

Demystify sustainable technology and show its feasibility.

-

Build trust in waste-to-energy innovation.

-

Promote behavior change by encouraging waste sorting, reduced consumption, and recycling efforts.

In short, pyrolysis doesn’t just convert waste—it converts mindsets. By using it as a tool for education, communities can be empowered to embrace sustainable thinking, innovate locally, and take meaningful action toward climate goals.

🚀 The Future of This Innovation: Pyrolysis

Pyrolysis is poised to play a transformative role in the future of sustainability, circular economies, and waste management. As the global community races to meet climate goals and reduce dependency on fossil fuels, pyrolysis stands out as a scalable, adaptable, and increasingly efficient solution.

🌍 A Pillar in the Circular Economy

As more governments and industries shift toward zero-waste systems, pyrolysis will become a core technology in circular waste streams. Rather than incinerating or landfilling plastics, tires, and biomass, pyrolysis enables the recovery of valuable resources—like synthetic fuels, biochar, and raw chemical feedstocks—that can be reintegrated into the production cycle.

💡 Tech Integration & Smart Systems

The future of pyrolysis will include smarter, more automated systems:

-

AI and IoT integration for real-time monitoring, emissions control, and energy optimization.

-

Modular micro-pyrolysis units that can be deployed in rural or remote locations.

-

Blockchain or digital tracking for waste input transparency and byproduct traceability.

This evolution will allow for decentralized, intelligent waste-to-resource networks across both developed and developing regions.

🌱 Green Fuel and Energy Transition

With ongoing improvements in feedstock handling and process efficiency, pyrolysis oil is expected to become a more viable substitute for diesel and industrial fuels. As demand for low-carbon energy grows, pyrolysis-derived fuels could:

-

Serve as transition fuels in heavy industry and transportation.

-

Be co-processed in existing refinery infrastructure.

-

Help reduce dependency on virgin crude oil.

🏙️ Urban and Industrial Deployment

In urban centers and industrial zones, pyrolysis facilities will likely be integrated into smart city infrastructure—diverting municipal solid waste while generating local energy or raw materials for manufacturing. Industries with high plastic use, like packaging or automotive, may build closed-loop systems around pyrolysis to recover and reuse materials internally.

🔭 Policy, Investment, and Global Adoption

International focus on ESG (Environmental, Social, Governance) standards, carbon markets, and plastic bans will likely accelerate:

-

Public-private partnerships to fund pyrolysis infrastructure.

-

Regulatory frameworks to certify pyrolysis byproducts for commercial use.

-

Exportable models to support developing nations struggling with waste pollution.

In summary, pyrolysis is not a fringe innovation—it is a frontier one. As awareness, regulation, and innovation converge, pyrolysis will help reimagine waste as a resource, reshape industrial systems, and redefine what’s possible in our pursuit of a sustainable future.

Sign up for Flobase Interactive

Explore the interactive world of flipbooks, eBooks, audiobooks and courses and join the global and personal growth revolution.

Sustainability Around the World

Get notified on when we post new innovations, cities and sustainability resources.

Reviews of Thermal Conversion Technologies

must try

Great post! I’ve been exploring natural remedies lately, and growing my own medicinal herbs at home has been a truly rewarding experience. If anyone’s interested in starting their own herbal garden, this Medicinal Garden Kit I found is super helpful – it comes with powerful healing herbs and an easy guide for beginners.

Recommended

Thank you for your valuable information. Hello everyone, my name is vidhya. I am from India but due to job regularly traveling to us,uk and all other countries. So My family also have to travel with me and my family is small. I have tried a few medicinal garden kits, and the results with this one are outstanding. The quality of the plants and the comprehensive guide set it apart. So much value for the price. It helps our family a lot. I personally highly recommend it to you. Thank you.

For more information you can check here:

Leave a Reply