Thermal Conversion Technologies

Thermal Conversion Technologies transform waste into energy or reusable materials using controlled heat processes—offering powerful solutions for waste reduction and sustainable energy generation.

Thermal Conversion Technologies

Thermal Conversion Technologies transform waste into energy or reusable materials using controlled heat processes—offering powerful solutions for waste reduction and sustainable energy generation.

Thermal Conversion Technologies

- Scores

- Sustainability Insights

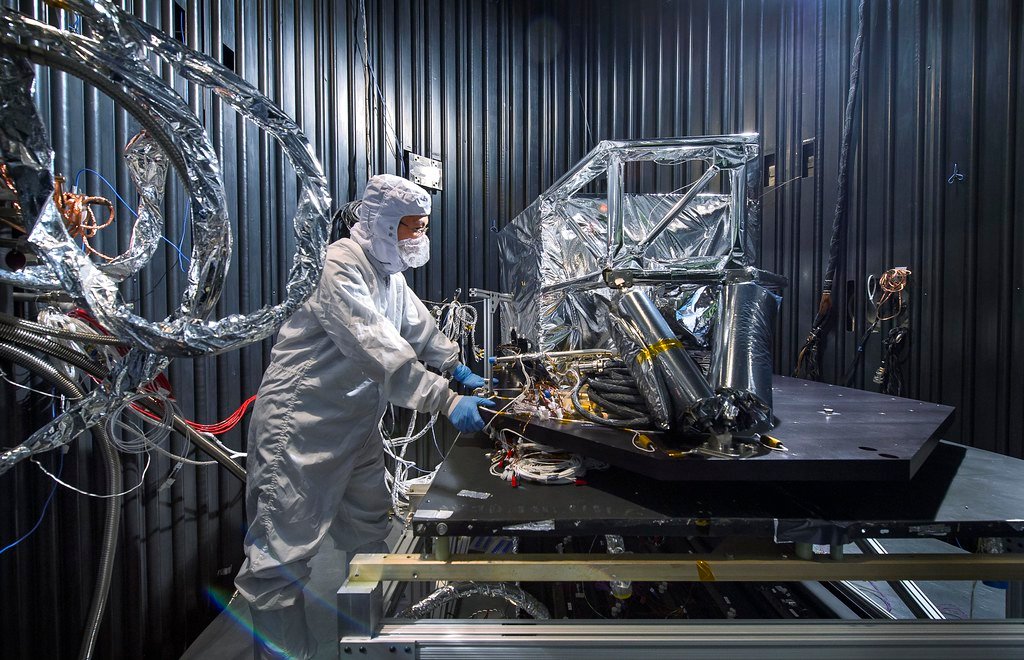

- Photos

- Video

- How It Works

- Sustainability Impact

- Cost and Affordability

- DIY and Community Use Cases

- Scalability & Industry Applications

- Innovation Metrics & Performance Data

- Alignment with Global Sustainability Goals

- Renewable Energy & Resource Integration

- Education & Awareness Potential

- The Future of This Innovation

✅ Overall Impact Score

♻️ Circularity Score

⚡ Energy Efficiency Score

🌱 Environmental Impact Score

💰 Affordability Score

🔋 Renewable Integration Score

🛠️ DIY Accessibility Score

📈 Scalability Score

🧪 Innovation Score

💡 Practical Usability Score

🌍 Global Sustainability Alignment Score

📦 Material Sustainability Score

🏘️ Community Impact Score

🚚 Supply Chain Sustainability Score

🧠 Educational Value Score

🚀 Future Readiness Score

🔒 Disclaimer

The information provided on this page is for educational and informational purposes only. While Sustainable World strives to ensure the accuracy and relevance of the content, including innovation scores, environmental impact claims, and sustainability assessments, we do not guarantee completeness, accuracy, or timeliness.

🔬 All innovation insights, metrics, and scoring systems reflect Sustainable World‘s independent analysis and methodology. These are not endorsements or certifications of product safety, environmental claims, or regulatory compliance. Users should conduct their own research or consult qualified professionals before acting on any information found here.

💡 Some insights may be influenced by AI-assisted content generation and publicly available data, which we analyze and format using proprietary frameworks. Always verify technical, scientific, or safety data with original sources when making decisions related to environmental practices, purchasing, or implementation.

🔗 This site contains affiliate links to third-party products or services. We may earn a commission at no additional cost to you if you make a purchase through these links. However, product inclusion does not imply sponsorship or official partnership unless explicitly stated.

💼 Innovations, technologies, and sustainability practices vary widely by location, application, and scale. Suitability, performance, and feasibility will differ based on local infrastructure, regulations, and individual context.

📉 Sustainable World is not liable for any direct or indirect damages or losses incurred from the use of information on this site.

Overview:

Thermal Conversion Technologies encompass a range of processes like pyrolysis, gasification, and plasma arc systems that convert organic and inorganic waste into usable energy, fuels, or raw materials. Unlike traditional incineration, these methods occur in low-oxygen or oxygen-free environments, minimizing harmful emissions while maximizing energy recovery. These innovations are reshaping waste management, energy systems, and circular economies around the world.

These systems are increasingly used for managing plastics, agricultural waste, biomass, and municipal solid waste—diverting tons of potential landfill matter into sustainable power and industrial feedstocks. By integrating with smart sensors, energy grids, and closed-loop recycling systems, thermal conversion is poised to become a backbone of global green infrastructure.

🌱 Environmental Impact

📉 Waste Reduction

Diverts up to 90% of waste from landfills, including plastics and organic matter.

💧 Resource Conservation

Recovers valuable energy and raw materials from non-renewable waste streams, reducing the need for virgin extraction.

⚡ Energy Efficiency

Some systems recover over 70% of energy in waste through advanced heat transfer and combined heat and power (CHP) setups.

🔁 Circular Economy Integration

Supports closed-loop systems by converting waste into reusable resources like syngas, biochar, and synthetic fuels.

📦 Material Innovation

Often paired with composite material recycling and post-consumer waste reprocessing.

🧪 Scientific Breakthrough

Advances in high-temperature plasma, oxygen control, and catalytic reactions have greatly improved performance and reduced emissions.

💡 Cost-Effectiveness

While initial setup can be high, long-term ROI is strong through energy generation, carbon credits, and tipping fees from waste diversion.

📊 Impact Metrics

Metrics include energy output (kWh/ton), landfill diversion rates, GHG emissions reduction, and material recovery percentages.

📱 Tech Integration

Frequently integrated with AI-driven energy monitoring, IoT waste tracking, and smart grid systems.

🧭 Alignment with SDGs

Supports SDG 7 (Affordable and Clean Energy), SDG 11 (Sustainable Cities), SDG 12 (Responsible Consumption), and SDG 13 (Climate Action).

🏘️ Community Benefit

Creates green jobs, reduces community exposure to pollutants, and improves public health in urban areas.

📚 Educational Value

Demonstrates cutting-edge solutions in energy science and circular economy concepts, ideal for STEM education and public awareness campaigns.

🏗️ Built Environment Compatibility

Can be integrated into eco-industrial parks, municipal utilities, and community-scale waste facilities.

🚀 Future Potential

Positioned to play a major role in decentralized energy production and zero-waste cities of the future.

🎯 Target Market Fit

Ideal for municipalities, waste management companies, sustainable agriculture, and industrial parks.

📉 Lifecycle Assessment

Studies show full lifecycle CO₂ emissions are far lower than traditional incineration or landfilling, especially when capturing and reusing outputs.

🏭 Industrial Applications

Already transforming sectors like waste-to-fuel, fertilizer production, cement, and synthetic gas markets.

🛠️ DIY Applications

While not feasible for home use, small-scale modular pyrolysis kits are emerging for rural farms and eco-villages.

🌍 Global Scalability

Used in both developed and developing countries, adaptable to diverse waste streams and energy infrastructures.

🛠️ Ease of Implementation

Requires infrastructure and regulatory alignment, but modular systems are making adoption more accessible globally.

🔒 Disclaimer

The information provided on this page is for educational and informational purposes only. While Sustainable World strives to ensure the accuracy and relevance of the content, including innovation scores, environmental impact claims, and sustainability assessments, we do not guarantee completeness, accuracy, or timeliness.

🔬 All innovation insights, metrics, and scoring systems reflect Sustainable World‘s independent analysis and methodology. These are not endorsements or certifications of product safety, environmental claims, or regulatory compliance. Users should conduct their own research or consult qualified professionals before acting on any information found here.

💡 Some insights may be influenced by AI-assisted content generation and publicly available data, which we analyze and format using proprietary frameworks. Always verify technical, scientific, or safety data with original sources when making decisions related to environmental practices, purchasing, or implementation.

🔗 This site contains affiliate links to third-party products or services. We may earn a commission at no additional cost to you if you make a purchase through these links. However, product inclusion does not imply sponsorship or official partnership unless explicitly stated.

💼 Innovations, technologies, and sustainability practices vary widely by location, application, and scale. Suitability, performance, and feasibility will differ based on local infrastructure, regulations, and individual context.

📉 Sustainable World is not liable for any direct or indirect damages or losses incurred from the use of information on this site.

🌱 How It Works: Thermal Conversion Technologies

Thermal Conversion Technologies harness heat to break down materials—most commonly waste—into usable forms of energy or raw materials. These systems offer a powerful alternative to landfilling by transforming organic or synthetic matter through controlled thermal processes.

At their core, these technologies work by applying high temperatures to initiate chemical or physical changes in feedstock (such as plastic, biomass, or municipal waste) without relying solely on combustion. Common methods include pyrolysis, gasification, and torrefaction—each designed to optimize energy recovery while minimizing emissions.

🔬 Here’s a simplified breakdown of the process:

-

Input Stage: Waste materials—such as plastics, biomass, or sewage sludge—are collected, pre-treated, and loaded into a closed thermal system.

-

Thermal Processing: Depending on the system:

-

Pyrolysis breaks down materials in the absence of oxygen to produce synthetic gas, oil, or char.

-

Gasification uses limited oxygen to create syngas (a mixture of hydrogen and carbon monoxide).

-

Torrefaction gently roasts biomass at lower temperatures to produce a fuel-efficient, coal-like substance.

-

-

Output Stage: The result is energy-dense outputs such as bio-oil, synthetic gas, biochar, or clean heat, which can be used to power homes, fuel vehicles, or serve as industrial feedstock.

-

Byproduct Recovery: Many systems include ash or char capture, and some can reintegrate outputs into closed-loop circular systems—minimizing waste altogether.

What makes thermal conversion technologies stand out is their ability to:

-

Process hard-to-recycle waste streams

-

Reduce methane emissions from organic decay

-

Provide localized, scalable energy solutions

They are especially useful in urban waste management, rural energy independence, and emergency disaster zones where traditional infrastructure is limited.

♻️ Waste Reduction

Thermal conversion technologies play a pivotal role in diverting waste from landfills and incinerators. By breaking down plastics, biomass, and other difficult-to-recycle materials, these systems reduce overall waste volume by up to 90%, minimizing long-term environmental burden.

🌱 Environmental Impact

These technologies can significantly lower greenhouse gas emissions, particularly methane that would otherwise come from decomposing organic matter. When operated under controlled conditions, they also produce fewer air pollutants compared to traditional incineration.

💧 Resource Conservation

By recovering energy and usable byproducts (like biochar or syngas), thermal conversion reduces the need for extracting virgin fossil fuels. Some systems also recycle heat, further conserving natural resources.

⚡ Energy Efficiency

Modern pyrolysis and gasification systems are designed for energy recovery, producing biofuels or syngas that can be used for heating, electricity, or transportation—often with a higher net energy output than the energy used in the process.

🔁 Circular Economy Integration

Thermal conversion supports closed-loop systems by transforming waste into reusable resources. For example, char can be used as a soil amendment, while oils can become new fuels or industrial feedstocks.

📦 Material Sustainability

While not always using biodegradable materials, these systems extend the lifecycle of nonrenewables by recovering energy and preventing environmental leakage—especially critical for hard-to-manage waste streams like mixed plastics.

🧪 Scientific and Technological Innovation

Advancements in reactor design, temperature control, and emission filtration have made these systems safer, more efficient, and scalable. Integration with AI for process optimization and real-time monitoring enhances sustainability performance.

💡 Cost-Effectiveness

Though initial installation can be capital intensive, thermal conversion systems offer long-term ROI through reduced landfill fees, energy production, and byproduct sales. In developing regions, smaller units offer low-cost waste-to-energy solutions.

🏘️ Community and Health Benefits

By replacing open burning or unmanaged dumping, these technologies improve local air quality and public health. Decentralized systems also create green jobs and support local circular economies.

🌍 Global Sustainability Alignment

Thermal conversion contributes to several UN Sustainable Development Goals, including:

-

SDG 7: Affordable and Clean Energy

-

SDG 11: Sustainable Cities and Communities

-

SDG 12: Responsible Consumption and Production

-

SDG 13: Climate Action

💰 Initial Investment Costs

Thermal conversion technologies—especially pyrolysis, gasification, and plasma arc systems—often require moderate to high upfront capital depending on scale. Small-scale units for rural or community use may start at a few thousand dollars, while industrial systems can reach hundreds of thousands to millions. Costs generally include:

-

Equipment and installation

-

Safety and emissions control systems

-

Infrastructure modifications

-

Training and maintenance setup

💡 Operating Costs

Operating costs vary based on feedstock, energy inputs, and labor. Many systems are designed to be self-sustaining or partially powered by the energy they produce, reducing net operational costs over time. Key recurring expenses include:

-

Energy for startup and controls

-

Maintenance and part replacement

-

Labor and monitoring (can be automated in advanced systems)

-

Regulatory compliance (e.g., emissions testing)

📈 Return on Investment (ROI)

Despite upfront costs, thermal conversion technologies often offer strong long-term ROI, especially when:

-

Tipping fees or landfill costs are high

-

Recovered byproducts (bio-oil, syngas, char) are sold or reused

-

Energy is generated for internal use (lowering utility bills)

-

Carbon credits or circular economy incentives apply

ROI periods can range from 2–10 years, depending on system efficiency, scale, and regional market conditions.

🌱 Affordability for Communities

Modular, decentralized versions are becoming more affordable for municipalities, eco-villages, and even farms, with some models targeting developing regions. Innovations in 3D printing and low-cost manufacturing are also helping bring DIY or low-tech systems into community use.

🛠️ Summary of Cost-to-Benefit

-

High initial cost (esp. for industrial scale)

-

Low-to-moderate operating cost with potential energy self-sufficiency

-

Multiple revenue streams from outputs

-

Grants and subsidies available in some regions (e.g., green energy programs)

Thermal conversion stands out as a cost-effective solution in the long run, especially when integrated into broader waste management or energy recovery strategies.

🛠️ DIY and Community Use Cases

While thermal conversion technologies are powerful tools for waste management and energy recovery, their complexity and safety requirements limit their use in DIY or small-scale community settings.

For DIY applications, only low-tech systems like biochar kilns and TLUD (Top-Lit UpDraft) stoves are considered safe and practical. These units use controlled pyrolysis to convert biomass into biochar for soil enrichment, offering environmental and agricultural benefits without the high temperatures or toxic byproducts associated with more complex waste processing.

However, most gasification, plastic-to-fuel, or advanced pyrolysis systems are not recommended for home or community builds due to:

-

The need for precise temperature control (400–800°C)

-

The risk of toxic emissions (e.g., dioxins, CO, benzene)

-

The requirement for air scrubbers and gas cleaning equipment

-

Regulatory restrictions in many regions

Educational institutions may use lab-scale models for demonstration purposes, but full-scale thermal conversion is best reserved for industrial or professionally managed environments.

In short: thermal conversion has limited safe DIY potential — best used under supervision or in simplified, biochar-focused setups.

For communities interested in sustainability, the best entry point is often collaboration with local universities, agricultural programs, or green tech initiatives exploring modular and mobile thermal systems designed for safe and regulated use.

📈 Scalability & Industry Applications

Thermal Conversion Technologies are highly scalable and play a growing role in industrial sustainability strategies around the world. Their ability to transform organic and plastic waste into usable outputs like fuel, char, and syngas makes them attractive to a range of sectors seeking circular economy solutions.

Industrial Scalability

Modern pyrolysis, gasification, and depolymerization systems can be deployed at various scales, from modular skid-mounted units to full-scale waste processing plants capable of handling tons of material daily. These systems are increasingly being adopted in:

-

Municipal solid waste facilities

-

Agricultural operations (processing crop waste into biochar)

-

Plastic recycling plants (converting mixed plastic waste into oil or fuel)

-

Chemical industries (recovering solvents and hydrocarbons)

Sector Applications

-

Energy Sector – Converts biomass or waste into syngas and bio-oil for power generation.

-

Agriculture – Uses biochar to improve soil quality and sequester carbon.

-

Manufacturing – Repurposes production scrap or waste into energy or raw materials.

-

Urban Waste Management – Diverts waste from landfills while generating renewable energy.

-

Shipping and Aviation – Explores low-sulfur fuels derived from waste plastics.

Scalability Challenges

Despite its potential, widespread adoption faces a few challenges:

-

High upfront investment and operational complexity

-

Need for continuous feedstock supply

-

Regulatory and environmental permitting

-

Public perception and emissions compliance

That said, decentralized thermal systems are emerging, especially in regions with limited access to recycling infrastructure. Mobile pyrolysis units and compact gasifiers are helping rural and developing areas convert biomass into energy without grid dependence.

In Summary: Thermal conversion is a mature, scalable solution ideal for industries aiming to reduce emissions, close material loops, and generate energy from waste. While not suitable for every context, it offers a high-impact opportunity when properly integrated into larger sustainability frameworks.

📊 Innovation Metrics & Performance Data

Thermal Conversion Technologies—such as pyrolysis, gasification, and depolymerization—are evaluated through a set of key performance indicators (KPIs) that reflect their efficiency, sustainability, and economic viability. These metrics help industry leaders, policymakers, and sustainability analysts determine the true impact and potential of these systems.

♻️ Waste Reduction Efficiency

One of the most compelling metrics is waste diversion. Advanced pyrolysis systems can reduce the volume of waste by up to 90%, turning previously non-recyclable materials into usable outputs like synthetic fuels, char, and gas. This directly eases pressure on landfills and incinerators.

⚡ Energy Output vs. Input (EROI)

Thermal conversion typically has a positive energy return on investment (EROI), especially when processing high-carbon materials like plastics or biomass. Modern systems can achieve EROIs ranging from 3:1 to 6:1, depending on feedstock and system design.

🌱 Emission Reduction Potential

When optimized with emissions control technologies, thermal systems emit significantly fewer pollutants than traditional incineration. Low-oxygen conditions prevent full combustion, which reduces NOx, dioxins, and CO₂ output. Many systems achieve up to 70% lower CO₂ emissions compared to open burning or standard waste-to-energy facilities.

🔋 Output Purity and Usability

-

Biochar: Carbon content of 70–90%, ideal for soil enhancement and carbon sequestration.

-

Syngas: High in hydrogen and carbon monoxide, usable in turbines or upgraded to fuels.

-

Bio-oil: Can be refined into diesel or heating oil, depending on the process.

📦 Feedstock Versatility

A major innovation point is the ability to process mixed waste streams, including contaminated plastics, agricultural residue, and municipal waste. Some commercial systems report over 80% conversion efficiency across varied materials.

💰 Cost per Ton Processed

The cost of processing waste via thermal conversion varies by scale, but it typically falls between $30–$100 per ton—comparable or cheaper than landfill tipping fees in many areas. Long-term contracts or carbon credits can further improve the economic case.

📉 Lifecycle Carbon Accounting

LCA (lifecycle assessment) models show net reductions in carbon emissions, particularly when the process displaces fossil fuel energy or sequesters carbon via biochar. Some systems demonstrate net-negative emissions, depending on the use case.

🔍 Real-World Performance Case Studies

-

Finland & Germany have adopted pyrolysis at municipal levels for mixed plastic waste.

-

Japan utilizes compact gasification units in disaster zones for localized energy.

-

U.S. startups have developed mobile pyrolysis units that turn farm waste into marketable char and fuel.

🌍 Alignment with Global Sustainability Goals

Thermal Conversion Technologies directly support multiple United Nations Sustainable Development Goals (SDGs) by addressing the urgent need for sustainable waste management, clean energy, and climate action.

♻️ SDG 12: Responsible Consumption and Production

Thermal technologies like pyrolysis and gasification divert waste from landfills and oceans, converting plastics, biomass, and agricultural residues into useful byproducts. This fosters a circular economy, reduces dependence on virgin materials, and minimizes pollution.

⚡ SDG 7: Affordable and Clean Energy

By producing syngas, bio-oil, and other renewable fuels, these systems contribute to decentralized, clean energy generation—especially in off-grid or energy-scarce regions. This enables broader access to affordable and locally produced power, reducing reliance on fossil fuels.

🌱 SDG 13: Climate Action

These technologies help cut greenhouse gas emissions by:

-

Reducing methane from landfills

-

Lowering CO₂ emissions through efficient waste-to-energy conversion

-

Supporting carbon-negative outcomes when paired with biochar sequestration.

This supports global carbon reduction targets and national climate strategies.

🏘️ SDG 11: Sustainable Cities and Communities

Thermal conversion solutions can be integrated into urban waste systems to manage local refuse sustainably. When adopted by cities, these technologies improve air quality, waste sanitation, and local energy resilience.

💧 SDG 6: Clean Water and Sanitation

By reducing the volume of improperly managed waste and plastics, these technologies help prevent waterway contamination and protect aquatic ecosystems—especially in regions lacking reliable waste infrastructure.

🏭 SDG 9: Industry, Innovation, and Infrastructure

Thermal conversion is a rapidly evolving field that drives green innovation and supports the creation of resilient industrial infrastructure, from mobile biochar units to municipal-scale energy recovery systems.

💰 SDG 8: Decent Work and Economic Growth

With scalable deployment, these technologies offer green job opportunities in engineering, operations, and maintenance—especially in rural and developing regions.

🔋 Renewable Energy & Resource Integration

Thermal Conversion Technologies play a powerful role in bridging the gap between waste management and renewable energy production. By converting organic and synthetic waste into usable energy forms such as syngas, bio-oil, and heat, these systems function as decentralized energy generators that complement existing renewable energy infrastructure.

⚡ Waste-to-Energy Synergy

Unlike intermittent renewables like solar or wind, thermal conversion offers continuous, controllable energy output. This reliability makes it an ideal partner to balance grids powered by variable renewables. Technologies like pyrolysis and gasification provide dispatchable energy that can be scaled up or down depending on demand.

🔁 Closed-Loop Resource Use

Many thermal conversion systems are designed to reuse their byproducts. For example:

-

Biochar from biomass pyrolysis can be returned to soil, sequestering carbon and improving agricultural productivity.

-

Recovered heat from gasification or combustion can be used in industrial processes or community heating systems.

-

Syngas can power combined heat and power (CHP) units, offering both electricity and thermal energy.

This circular integration of resources reduces dependence on virgin fuels, cuts emissions, and supports the development of self-sustaining energy ecosystems.

🔌 Integration with Renewable Energy Systems

Some advanced systems are now being designed to run on or alongside renewable energy inputs:

-

Solar-powered thermal reactors for off-grid waste conversion.

-

Battery storage hybridization, where excess energy from solar or wind is stored and used to initiate pyrolysis or maintain reactor temperatures.

These innovations allow thermal technologies to enhance grid flexibility, stabilize energy storage solutions, and contribute to cleaner, decentralized energy systems worldwide.

🌍 Localized Renewable Support

In developing regions or disaster-prone zones, portable thermal units offer energy autonomy. By processing local biomass, these systems reduce reliance on imported fuels and offer sustainable, on-demand power generation using locally available resources.

📚 Education & Awareness Potential

Thermal Conversion Technologies offer significant educational value and play a key role in raising public awareness about sustainability, waste management, and alternative energy systems. Their integration into educational programs, workshops, and community initiatives helps demystify advanced environmental technologies and encourages deeper engagement with real-world climate solutions.

🧠 Real-World Learning Opportunities

Thermal systems—such as small-scale gasifiers, demonstration pyrolysis units, or biochar kilns—can be adapted for use in:

-

STEM education programs in high schools and universities.

-

Environmental science and engineering curriculums, providing hands-on learning with thermodynamics, chemistry, and materials science.

-

Workshops and maker spaces where communities explore energy production, waste valorization, and DIY sustainability.

These applications allow students and learners to see the circular economy in action, understanding how everyday waste can be turned into heat, power, or carbon-rich soil additives.

🌎 Raising Sustainability Awareness

Demonstrating how trash becomes energy or how biomass becomes biochar captures attention and transforms abstract sustainability ideas into tangible processes. These technologies:

-

Make climate action visible and relatable.

-

Encourage responsible consumption and waste separation.

-

Inspire curiosity about closed-loop systems and regenerative practices.

Many public installations and eco-parks already use interactive exhibits to show the step-by-step process of thermal conversion, making complex science accessible to the public.

🛠️ Skill Building & Community Engagement

Workshops around biochar production, composting heat, or simple gasifier builds help:

-

Empower communities with sustainable tools.

-

Teach practical skills in fabrication, energy management, and resource efficiency.

-

Encourage civic engagement through neighborhood-scale projects.

These educational opportunities not only spread knowledge but also build local capacity for sustainability innovation.

🚀 The Future of This Innovation

Thermal Conversion Technologies are poised to play a transformative role in the future of sustainable development, particularly as global demand grows for clean energy, waste solutions, and carbon-neutral practices. From industrial-scale systems to research-driven breakthroughs, the trajectory of this innovation is expanding rapidly—driven by urgent climate goals, advances in engineering, and the circular economy movement.

🌍 Role in Climate Action & Waste Reduction

As landfills reach capacity and plastic pollution intensifies, thermal conversion systems—such as pyrolysis, gasification, and torrefaction—offer scalable alternatives for processing non-recyclable waste. These technologies:

-

Reduce landfill dependency

-

Lower methane emissions from organic waste

-

Create value from agricultural, plastic, and biomass waste streams

In the coming years, more municipalities and governments are expected to adopt thermal systems as part of their waste-to-energy infrastructure, especially where traditional recycling or composting is limited.

🔋 Next-Gen Renewable Integration

Emerging research is integrating thermal technologies with renewable energy systems—such as using solar concentrators to drive pyrolysis or coupling biochar production with battery storage microgrids. This positions thermal conversion not just as a waste solution, but as a dynamic energy contributor in hybrid systems.

Additionally, biochar, one of the most promising outputs of pyrolysis, is gaining recognition for its role in carbon sequestration, soil regeneration, and climate-smart agriculture—attracting increasing investment and research funding.

🧠 AI, Automation & Innovation

Future systems will likely leverage:

-

AI and machine learning to optimize thermal reactions in real-time

-

Automated waste sorting and feedstock preparation

-

Smaller, modular units for use in rural or off-grid environments

Such advancements will make thermal conversion more efficient, safer, and accessible—extending its impact to new markets and use cases.

🌐 Policy & Global Sustainability Alignment

With climate frameworks like the UN SDGs and Paris Agreement calling for urgent emissions cuts, thermal conversion is being recognized as a practical pathway to help countries meet targets related to:

-

Clean energy (SDG 7)

-

Sustainable cities (SDG 11)

-

Responsible consumption and production (SDG 12)

-

Climate action (SDG 13)

Expect to see expanded government incentives, carbon credits, and grants supporting the deployment of these systems across both developing and industrialized nations.

Sign up for Flobase Interactive

Explore the interactive world of flipbooks, eBooks, audiobooks and courses and join the global and personal growth revolution.

Sustainability Around the World

Get notified on when we post new innovations, cities and sustainability resources.

Reviews of Thermal Conversion Technologies

must try

Great post! I’ve been exploring natural remedies lately, and growing my own medicinal herbs at home has been a truly rewarding experience. If anyone’s interested in starting their own herbal garden, this Medicinal Garden Kit I found is super helpful – it comes with powerful healing herbs and an easy guide for beginners.

Recommended

Thank you for your valuable information. Hello everyone, my name is vidhya. I am from India but due to job regularly traveling to us,uk and all other countries. So My family also have to travel with me and my family is small. I have tried a few medicinal garden kits, and the results with this one are outstanding. The quality of the plants and the comprehensive guide set it apart. So much value for the price. It helps our family a lot. I personally highly recommend it to you. Thank you.

For more information you can check here:

Leave a Reply